Updating ...

Our AddressNo.85, Khajeh Abdollah Ansari Ave., Shariati St., Tehran-Iran |

Phone+98 21 22888670-2 |

info@ngnir.com |

CONTACT US |

Import

Updating

Updating...

Iron alloys containing chromium, manganese, molybdenum, silicon, titanium, tungsten, vanadium and other elements in varying proportions. Ferroalloys are added to steel during the manufacturing process to achieve the desired degree of corrosion resistance, heat resistance, tensile strength, yield strength and other qualities.

The main ferroalloys are:

- FeAl – ferroaluminum

- FeB – ferroboron

- FeCe – ferrocerium

- FeCr – ferrochromium

- FeMg – ferromagnesium

- FeMn – ferromanganese

- FeMo – ferromolybdenum

- FeNb – ferroniobium, also called ferrocolumbium

- FeNi – ferronickel (and nickel pig iron)

- FeP – ferrophosphorus

- FeSi – ferrosilicon

- FeSiMg – ferrosilicon magnesium (with Mg 4 to 25%), also called nodulizer

- FeTi – ferrotitanium

- FeU – ferrouranium

- FeV – ferrovanadium

- FeW – ferrotungsten

- SiMn - Silicomanganese

NGN supply ferroalloys for its valued customers according their needs.

Ethylene Dichloride (EDC) is made by the chlorination of ethylene via one of two processes: direct chlorination using pure chlorine and ethylene; or oxychlorination in which ethylene reacts with chlorine in hydrogen chloride. Many EDC/VCM plants employ a combination of chlorination and oxychlorination to consume the hydrogen chloride by-product from the cracking of EDC to VCM.

The chemical compound 1,2-dichloroethane, commonly known as ethylene dichloride (EDC), is a chlorinated hydrocarbon, mainly used to produce vinyl chloride monomer (VCM, chloroethene), the major precursor for PVC production. It is a colorless liquid with a chloroform-like odor. Ethylene dichloride is also used generally as an intermediate for other organic chemical compounds, and as a solvent.

Ethylene dichloride is produced through the iron(III) chloride catalyzed reaction of ethene (ethylene) and chlorine.

EDC is used primarily as a raw material in the manufacture of vinyl chloride monomer (VCM). The vinyl chloride, in turn is used to manufacture polyvinyl chloride (PVC) resin. EDC is also used as an intermediate in the manufacture of chlorinated and fluorinated compounds. EDC has been used as a solvent in the textile, metal cleaning and adhesive industries.

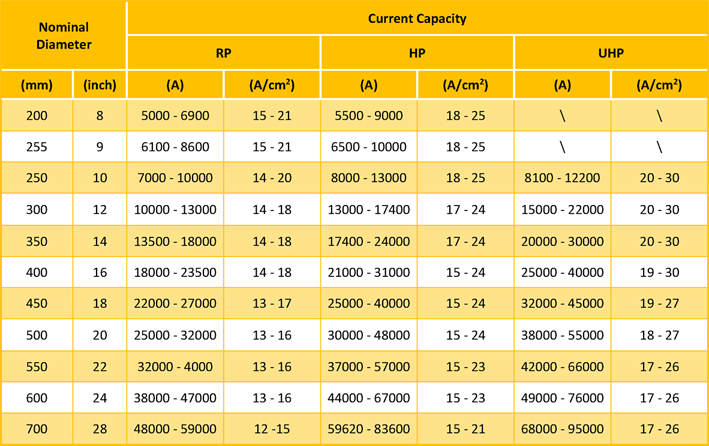

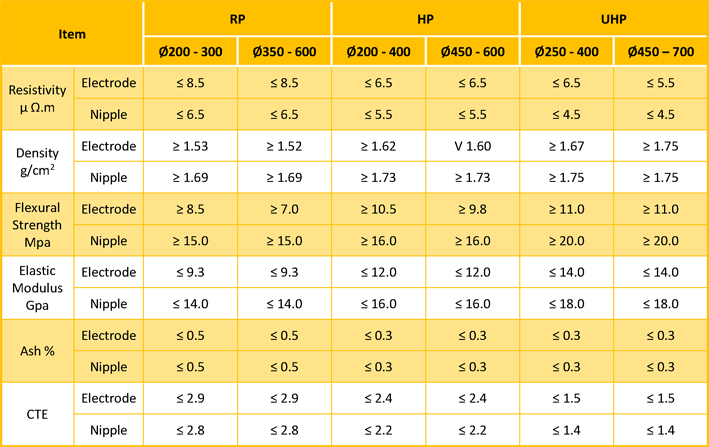

Graphite electrodes serve to transfer the electrical energy from the power supply to the steel melt in the EAF bath. They are typically made using premium petroleum needle coke, coal tar pitch, and some additives.

Electrode consumption varies between 1.8 and 9.9 kg/t of liquid steel (Parkash, 2010) depending on the process characteristics and electrode quality. Ameling et al. (2011) reported that the electrode consumption in Germany in 2010 was approximately 1.1 kg per ton as a result of the reduction of time between the taps to 40 min and consequently the lower electricity consumption (345 kWh/t). Electrodes are classified as regular grade or premium grade on the basis of their physical properties (International Iron and Steel Institute, 1983).

For DC Furnaces (direct current furnaces) / Size: 22-32 inches

Electrodes for DC furnaces, which require 1 column of graphite electrodes. High maximum current density. The diameter of these electrodes is getting bigger: the current maximum diameter is 32 inches (801 mm).

For AC Furnaces (alternating current furnaces) / Size: 16-28 inches.

Alternating current furnaces require 3 columns of graphite electrodes. They mostly use 20-28 inch electrodes, the standard size in electric furnaces.

For LF Furnaces (refining furnaces) / Size: 10-18 inches

These electrodes are for refining materials like molten steel. LF Furnaces have a smaller capacity than DC.

Sodium carbonate serves as a flux for silica, lowering the melting point of the mixture to something achievable without special materials. This "soda glass" is mildly water-soluble, so some calcium carbonate is added to the melt mixture to make the glass produced insoluble.

The principal applications of sodium carbonate are in the manufacture of glass and the production of chemicals. It is also used in processing wood pulp to make paper, in making soaps and detergents, in refining aluminum, in water softening, and in many other applications.

The major uses of heavy sodium carbonate are as a solid, particularly in making glass, where it is used as a flux in the melting of silica (sand). The uses for light sodium carbonate are traditionally where the chemical is required in solution.

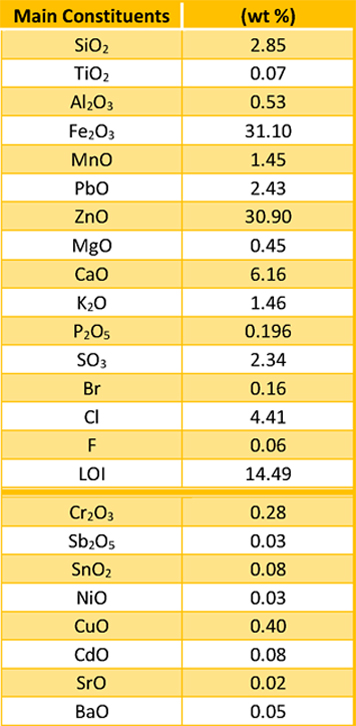

Electric arc furnace dust (EAFD) is a waste from steel recycling in an electric arc furnace. Due to the waste mainly consisting of zinc ferrite along with a small amount of heavy metals such as lead and chromium, EAFD is categorized as a toxic waste. Even though proper treatments of EAFD offer crude zinc oxide and iron oxide, such appropriate EAFD recycling techniques have not yet been established in Thailand. The simplest way to reduce its toxicity is glassification. According to the EAFD’s chemical composition, it is possible to use it as a raw material in decorative ceramic glazes which contain zinc and iron oxides.

Zinc bearing wastes such as electric arc furnace dust (EAFD) obtained from steel making constitute an important resource for zinc extraction. Inclusion of heavy metals such as Pb, Cd, Cu, Cr, Ni, etc., in these wastes makes them hazardous to use and/or dispose. In the present research work, leaching kinetics of EAFD with sulfuric acid has been investigated and various experimental parameters such as concentration of lixiviant, stirring rate, sample particle size, liquid/solid proportion, and temperature of the reaction have been optimized.

Calcined petroleum coke (CPC) is the product from calcining petroleum coke. This coke is the product of the coker unit in a crude oil refinery. The calcined petroleum coke is used to make anodes for the aluminium, steel and titanium smelting industry.

Calcined Petroleum Coke is a critical ingredient in the production of aluminum. It is created by placing high quality raw "green" petroleum coke into rotary kilns, where it is heated to temperatures between 1200 to 1350 degrees C (2192 to 2460 F). The high temperatures remove excess moisture, extract all remaining hydrocarbons and modify the crystalline structure of the coke, resulting in a denser more electrically conductive product. In a matter of hours, calcined petroleum coke is cooled from 1350 degrees C to less than 200 degrees C, when it can be safely handled and transported to storage silos or placed directly into shipping containers, trucks, railcars, barges or vessels.

Calcined petroleum coke has a sponge-like structure which plays an important role in the making of anodes. The pores allow binding material to penetrate through the coke particles and form a solid carbon block, through which aluminum smelters conduct electricity into their smelting pots. Over time, the anodes are consumed, roughly at the rate of 40 tons of calcined petroleum coke for each 100 tons of aluminum produced. Currently, there is no known commercially viable substitute for calcined petroleum coke in the fabrication and utilization of aluminum smelter anodes.

NGN will supply different specifications of CPC for its valued customers.

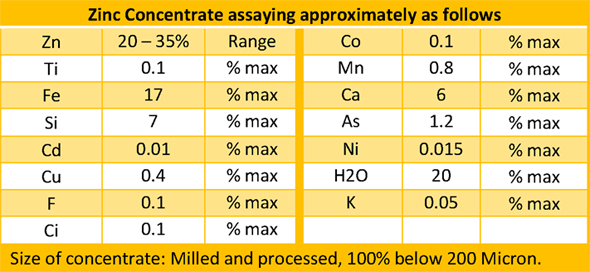

Zinc smelting is the process of converting zinc concentrates (ores that containzinc) into pure zinc. The most common zinc concentrate processed is zincsulfide, which is obtained by concentrating sphalerite using the froth flotation method.

NGN offers zinc concentrate with a majority zinc base component. Preparation of zinc concentrate typically involves the removal of water from an zinc solution.

Working Time

| Sat | 08:30 AM - 17:00 PM |

| Sun | 08:30 AM - 17:00 PM |

| Mon | 08:30 AM - 17:00 PM |

| Tue | 08:30 AM - 17:00 PM |

| Wen | 08:30 AM - 17:00 PM |

| Weekend | CLOSED |

English

English

Persian (Iran)

Persian (Iran)