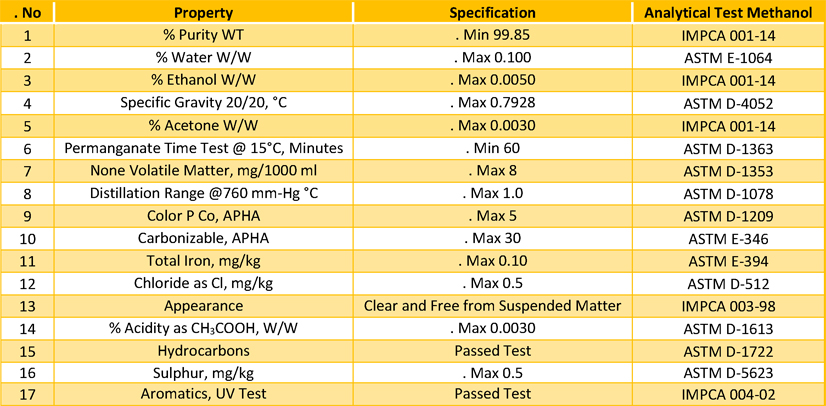

Methanol (CH3OH), also called methyl alcohol, wood alcohol, or wood spirit, the simplest of a long series of organic compounds called alcohols, consisting of a methyl group (CH3) linked with a hydroxy group (OH). Methanol was formerly produced by the destructive distillation of wood. The modern method of preparing methanol is based on the direct combination of carbon monoxide gas and hydrogen in the presence of a catalyst. Increasingly, syngas, a mixture of hydrogen and carbon monoxide derived from biomass, is used for methanol production.

NGN has exported Methanol around 200,000 MT to Middle East from reliable Petrochemical companies.

Usag

Nowadays, methanol is used as raw material in many industries, environment friendly fuel and also in a lot of other industries. Mainly we can name:

1- Formaldehyde production for use in MDF and plywood industry

2- Melamine resin production for use in range of utensil, inbuilt switches and ranges of industrial glue.

3- Acetic acid production for use in VAM and cellulose acetate in textile industry.

4- Methyl Metacrylate (PMAA) for use in laminates.

5- Methyl Tertiary Butyl Ether (MTBE) production as a gas online enhancer

6- Producing DME for substituting diesel fuel.

7- Mixing with petrol for car engine fuel usage.

8- Producing ethylene and propylene as raw material of petrochemical companies.

English

English

Persian (Iran)

Persian (Iran)