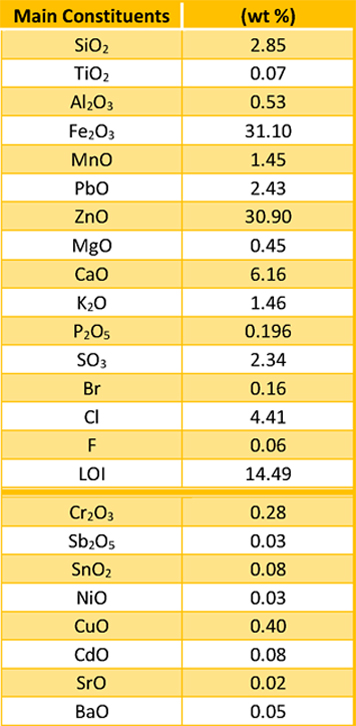

Electric arc furnace dust (EAFD) is a waste from steel recycling in an electric arc furnace. Due to the waste mainly consisting of zinc ferrite along with a small amount of heavy metals such as lead and chromium, EAFD is categorized as a toxic waste. Even though proper treatments of EAFD offer crude zinc oxide and iron oxide, such appropriate EAFD recycling techniques have not yet been established in Thailand. The simplest way to reduce its toxicity is glassification. According to the EAFD’s chemical composition, it is possible to use it as a raw material in decorative ceramic glazes which contain zinc and iron oxides.

Zinc bearing wastes such as electric arc furnace dust (EAFD) obtained from steel making constitute an important resource for zinc extraction. Inclusion of heavy metals such as Pb, Cd, Cu, Cr, Ni, etc., in these wastes makes them hazardous to use and/or dispose. In the present research work, leaching kinetics of EAFD with sulfuric acid has been investigated and various experimental parameters such as concentration of lixiviant, stirring rate, sample particle size, liquid/solid proportion, and temperature of the reaction have been optimized.

English

English

Persian (Iran)

Persian (Iran)